| Brand Name | DLSEALS |

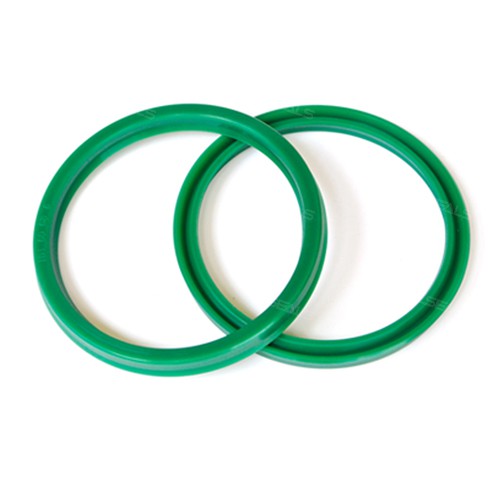

| Product name | Stainless steel o ring |

| Standard or Nonstandard | Standard or as request |

| Material | Stainless steel 304 |

| Color | Silver |

| Feature | Corrosion resistance |

| Application | Automobile, electrical appliance, cylinder, bearing |

● The physical and mechanical properties, PTFE is relatively high density, almost non-absorbent. Without tough resilience. It has a very small friction factor, showing excellent lubricity. PTFE static friction factor than the dynamic friction factor is less, and the ultra-low temperature to the melting point, the friction factor is almost unchanged. However, low hardness susceptible to other PTFE materials wear. If it can form a layer on the surface of the grinding material PTFE film, which reduces the amount of wear of PTFE to a considerable extent.

● Heat resistance, thermal stability of PTFE lies in the engineering plastics is extremely prominent. At 200 ℃ to the melting point, the decomposition very slow, very small amount of decomposition, heated at 200 ℃ month, less than a millionth of the amount of decomposition, is negligible. PTFE at -250 ℃ still crisp. Long-term use in -250 ~ 260 ℃. ● The electrical properties, PTFE is a highly non-polar material, with extremely excellent dielectric properties, prominently when more than 0 ℃, dielectric properties and does not affect the frequency with temperature, humidity and are not subject to influence of corrosive gas . PTFE volume resistivity and surface resistivity is the highest of all plastics, even after prolonged immersion in water, it will not drop significantly, at 100% relative humidity of the air, the surface resistivity remains unchanged. Crystallinity of PTFE at 50% to 80%, the dielectric strength is almost independent of the degree of crystallinity, and having the lowest dielectric constant. PTFE excellent arc resistance.